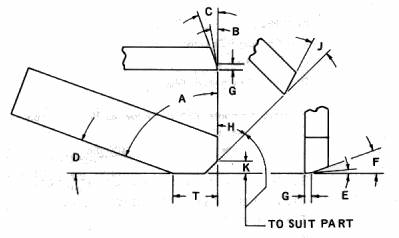

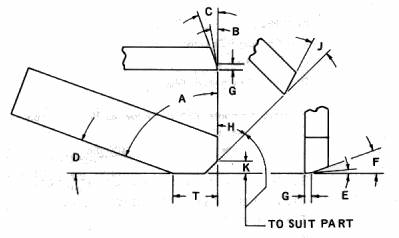

Genesee Blade Grinding Angles for Radial Hollow Mills |

Styles |

Blade Size |

A |

B |

C |

D |

E |

T |

F |

H |

J |

A L V G |

170 x 1/2 x 2 |

70° |

8° |

20° |

19° - 45' |

0° |

31/64 |

30° |

20° |

8° |

230 x 5/8 x 2 1/2 |

70° |

8° |

20° |

19°- 45' |

0° |

39/64 |

20° |

20° |

8° |

280 x 3/4 x 2 5/8 |

70° |

8° |

20° |

19°- 45' |

0° |

39/64 |

20° |

20° |

8° |

350 x 7/8 x 2 7/8 |

70° |

8° |

20° |

19°- 45' |

0° |

39/64 |

20° |

20° |

8° |

470 x 1 x 3 1/8 |

70° |

8° |

20° |

19°- 45' |

0° |

13/16 |

20° |

20° |

8° |

L-00, L-00-D

L-0, L-0-D

L-2, L-2-D |

110 x 11/32 x 1 1/4 |

70° |

8° |

20° |

19°- 45' |

0° |

17/64 |

35° |

20° |

8° |

170 x 1/2 x 2 |

70° |

8° |

20° |

19°- 45' |

0° |

31/64 |

30° |

20° |

8° |

230 x 1/2 x 2 |

70° |

8° |

20° |

19°- 45' |

0° |

31/64 |

20° |

20° |

8° |

R-1,R-2

R-3, R-4 |

110 x 11/32 x 1 1/16 |

70° |

8° |

20° |

19°- 45' |

0° |

7/32 |

35° |

20° |

8° |

170 x 1/2 x 1 13/16 |

70° |

8° |

20° |

19°- 45' |

0° |

7/16 |

30° |

20° |

8° |

230 x 1/2 x 1 13/16 |

70° |

8° |

20° |

19°- 45' |

0° |

7/16 |

20° |

20° |

8° |

T |

170 x 1/2 x 2 |

70° |

8° |

20° |

19°- 45' |

14° |

15/32 |

23° |

45° |

16 1/2° |

230 x 5/8 x 2 |

70° |

8° |

20° |

19°- 45' |

14° |

19/32 |

23° |

45° |

161/2° |

|